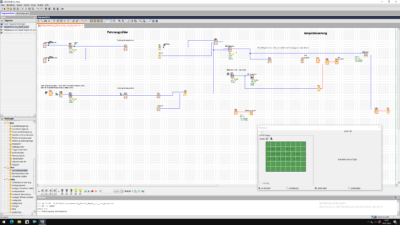

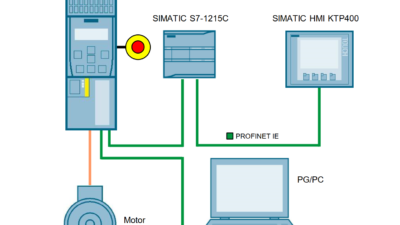

50 projects using Siemens S7-1215C, KTP400/KTP600, LEDs, and a potentiometer

Basic Projects (Getting Started with PLC and HMI)

- LED Control with Button – simple digital input control.

- LED Brightness Control (PWM) – using the potentiometer as an analog input.

- Start-Stop Button – using an RS flip-flop to control an output.

- Delayed ON/OFF LED Control – implementing TON, TOF timers.

- Pulse Counter from Button – counting button presses and displaying them on HMI.

- Energy-Saving Mode – turning off LEDs after inactivity.

- Random LED Blinking – generating pseudo-random signals.

- Displaying Potentiometer Value on HMI – using AI for visualization.

- RTC Clock on HMI – displaying the current time on the screen.

- Blinking LED – controlling an LED using a timer.

Intermediate Projects (Control Logic & HMI Diagnostics)

- LED Control from HMI – creating a simple user interface.

- Motor Speed Regulation (Simulation) – using the potentiometer to adjust PWM frequency.

- Alarm List on HMI – logging and clearing alarms.

- Fan Speed Simulation – adjusting speed based on potentiometer value.

- KTP Brightness Adjustment – changing the screen brightness based on RTC time.

- Production Counter – registering machine operation cycles.

- Manual/Automatic Mode Selection – switch modes via HMI.

- Selective LED Control – different lighting modes based on the potentiometer value.

- PIN Code Authorization on HMI – user authentication system.

- Garage Door Control (Simulation) – implementing open/close logic.

Advanced Projects (Enhanced Logic, Block Structures, Optimization)

- Temperature Regulation (Simulation) – using the potentiometer as a temperature sensor.

- Soft Start (Simulation) – smooth motor startup.

- Relay Timer Operation – advanced ON/OFF delay logic.

- RGB LED Control – changing LED colors based on AI input.

- Automatic Street Lighting – adjusting brightness based on time of day.

- Water Pump Control – simulating a water level system.

- Automatic Ventilation System – controlling a fan based on temperature.

- Advanced HMI Menu System – navigating multiple functions.

- Historical Data Logging – saving values to memory.

- PLC Error Monitoring and Diagnostics – displaying input/output states.

Experimental Projects (Advanced PLC Functions & HMI Communication)

- Modbus Communication (Optional) – learning industrial data exchange.

- Program Execution Time Analysis – optimizing PLC code.

- Device Control via Mobile App (Optional) – testing Web Server.

- PID Control (Simulation) – regulating temperature.

- Tank Filling Process Simulation – controlling a valve based on level.

- LED Scheduling – automatic switching based on a set time.

- Assembly Line Simulation – simulating production steps.

- Unauthorized Access Protection – PIN-based access control.

- Energy Consumption Analysis (Simulation) – monitoring loads.

- Fermentation Process Control (Simulation) – controlling temperature and humidity.

Mega Projects (Large, Comprehensive Control Systems)

- Simple Electronic Weighing System (Simulation) – calculating weight based on analog input.

- Batch Production System – managing production phases.

- Automatic Plant Watering – simulating soil moisture control.

- Product Sorting System – sorting outputs based on input parameters.

- Vibration Monitoring (Simulation) – detecting anomalies.

- Conveyor System Management – controlling transport mechanisms.

- Smart Home System (Simulation) – controlling lights, blinds, heating.

- Automated Fuel Dispensing System (Simulation) – user interface for fuel control.

- Industrial Marking System – tracking products in production.

- Advanced HMI with Animations – dynamically displaying system states.

Summary

This list of 50 projects will help you master TIA Portal, Siemens S7-1215C, and KTP HMI while developing your PLC programming skills.

Which project do you want to start with? Let me know, and I can help with implementation!

S7-1215c web control and data logging in Excel

Siemens S1215C PLC, with a focus on web control and data logging in Excel, offering a mix of automation, data handling, and visualization:

Beginner Projects:

- Basic Web Control for Lights and Motors: Create a simple web interface where you can control lights, motors, or other devices connected to the S1215C PLC via a browser.

- Remote Start/Stop Control: Build a basic web interface to remotely start or stop a motor or any other device connected to the PLC.

- Data Logging to Excel (via OPC UA)**: Collect data from sensors (e.g., temperature, pressure) and log it directly to an Excel sheet using OPC UA for remote monitoring.

- Temperature Monitoring and Web Display**: Read temperature sensor data with the PLC and display it on a webpage in real time.

- Web-Based Conveyor Control**: Use a web interface to control the speed and direction of a conveyor belt driven by the PLC.

- Simple Alarm System with Web Interface**: Build a home or small workshop alarm system that you can arm or disarm via a web interface, with email notifications.

- Excel-Based Production Counter**: Use the PLC to count items on a conveyor and log the count in an Excel sheet for simple production tracking.

Intermediate Projects:

- Web Dashboard for Multiple Sensors**: Build a dashboard to display real-time data from various sensors (temperature, humidity, etc.) on a webpage.

- Remote Pump Control with Web Interface**: Use a web-based control system to start and stop water pumps remotely, with real-time status monitoring.

- Energy Consumption Logging and Visualization**: Monitor energy consumption using current sensors, log the data to Excel, and generate reports for analysis.

- Temperature and Humidity Logging with Historical Data in Excel**: Record temperature and humidity data over time and generate graphs using Excel to visualize the data.

- Remote Machine Monitoring via Web Interface**: Build a web interface to monitor the status (running, stopped, faulted) of machines in real time.

- Automated Report Generation**: Create a system that logs production data and automatically generates a daily report in Excel, including charts and summaries.

- Web-Controlled Greenhouse Automation**: Automate a greenhouse system with web-based control for lighting, irrigation, and climate control, using data logged to Excel for trend analysis.

Advanced Projects:

- IoT-Enabled Smart Home Automation**: Use the PLC with a web interface to control lights, fans, and HVAC systems in a smart home setup, logging data to Excel for energy analysis.

- SCADA System with Web Access and Excel Reporting**: Develop a small-scale SCADA system where you monitor and control various processes through a web interface, while logging historical data to Excel for reporting.

- Web-Controlled Production Line**: Control an entire production line remotely through a web interface, including start/stop, speed control, and fault monitoring, while logging production data to Excel.

- Predictive Maintenance System**: Collect data from sensors on machine vibration, temperature, and run time, and log it to Excel. Use this data to predict when maintenance is needed, showing alerts on a web interface.

- Quality Control Logging and Web Visualization**: Use sensors to monitor product quality (dimensions, weight, etc.), log the data in Excel, and display quality trends and alerts on a web interface.

- Remote Data Acquisition and Control with Excel Export**: Create a remote data acquisition system that collects sensor data (temperature, pressure, etc.) and exports this data to Excel in real time, accessible via a web interface.

Required Components for Web and Excel Projects:

– OPC UA Server: This can help integrate the PLC data with Excel via OPC DA/UA communication.

– Web Server Setup: You can use Siemens’ TIA Portal with Web Server functionality to create web pages and control PLC operations remotely.

– Excel Integration Tools: For logging data to Excel, use Siemens’ LOGO! Soft Comfortwith integrated data logging features or custom scripts using OPC UA communication.

– Node-RED: This is an excellent tool for integrating web interfaces and PLC communication, especially for IoT and web-based control.

These projects leverage the web and data logging capabilities of the S1215C, enabling remote control and real-time monitoring with data analysis through Excel. You can further expand these ideas into more complex systems for industrial, home automation, or workshop use.

Factory I/O scenes:

🔹 Beginner-Level Scenes

- From A to B:Transport a box until it reaches a sensor.

Focus: Basic on/off control, sensor-actuator interaction.

- From A to B (Set and Reset):Similar to the first scene but introduces set/reset logic.

Focus: Latching mechanisms, flip-flop behavior.

- Filling Tank (Timers)

Fill and empty a tank using timers.

Focus: Timer operations, sequential control.

- Queue of Items (Counters)

Load and unload three boxes onto a conveyor.

Focus: Counting items, managing queues.

🔹 Intermediate-Level Scenes

- Pick & Place (Basic)Pick and place items from one conveyor into another.

Focus: Sequential movements, actuator coordination.

- Sorting by Height (Basic) Sort cardboard boxes by height using a chain transfer.

Focus: Sensor-based sorting, decision-making logic.

- Sorting by Height (Advanced)Sort cardboard boxes by height using a turntable.

Focus: Advanced sorting mechanisms, turntable control.

- Sorting by Weight Sort cardboard boxes by weight using a conveyor scale.

Focus: Analog value processing, weight-based sorting.

- Sorting Station: Separate green and blue items using a vision sensor.

Focus: Color detection, vision sensor integration.

- Separating Station: Separate blue and green parts into two conveyors.

Focus: Color-based sorting, diverter control.

🔹 Advanced-Level Scenes

- Assembler:Assemble parts made of lids and bases using a two-axis pick and place.

Focus: Assembly operations, multi-axis coordination.

- Assembler (Analog):Similar to the Assembler scene but incorporates analog values.

Focus: Analog signal processing, precise control.

- Automated Warehouse: Transport, store, and retrieve boxes from a rack.

Focus: Inventory management, storage/retrieval logic.

- Palletizer: Palletize cases in several layers.

Focus: Stacking operations, layer management.

- Production Line: Produce the same number of lids and bases by controlling two machining centers.

Focus: Synchronization, production balancing.

- Pick & Place XYZ: Place boxes onto pallets using a three-axis manipulator.

Focus: 3D movement control, complex sequencing.

- Elevator (Basic):Transport items through three different levels using two elevators.

Focus: Elevator control logic, level detection.

- Elevator (Advanced):Collect up to five items into a stackable box using an elevator.

Focus: Batch processing, stack management.

- Level Control: Control the liquid level (or flow) of a tank using a PID controller.

Focus: PID control, analog signal handling.

- Buffer Station: Buffer and separate up to five boxes.

Focus: Buffer management, flow control.

- Converge Station Converge two paths into a single one.

Focus: Merging logic, traffic control.

These scenes are accessible within Factory I/O by navigating to File > Open and selecting from the list of included scenes. They are read-only, so to customize them, save a copy to your “My Scenes” folder.

If you need assistance with specific scenes, such as setting up I/O tags, integrating with a particular PLC (e.g., Siemens S7-1200), or developing control logic, feel free to ask!

OPC UA Projekte

Mit OPC UA (Open Platform Communications Unified Architecture) lassen sich zu Hause viele interessante Projekte umsetzen, die dir helfen, praktische Erfahrungen mit diesem Kommunikationsprotokoll zu sammeln und gleichzeitig deine Automatisierungsfähigkeiten auszubauen. Hier sind einige Vorschläge für Projekte, die du zu Hause mit OPC UA realisieren kannst:

- Smart-Home-Steuerung mit OPC UA

Baue eine zentrale Steuerung für dein Smart Home auf Basis von OPC UA. Verbinde Geräte wie Beleuchtung, Heizung, Rollläden und andere smarte Komponenten über OPC UA mit einem zentralen Steuerungssystem (z.B. eine SPS oder ein Raspberry Pi). Du kannst die Kommunikation sicher und flexibel gestalten und Daten von verschiedenen Geräten überwachen und steuern.

- Überwachung des Energieverbrauchs

Integriere Sensoren und Zähler für den Strom-, Wasser- oder Gasverbrauch in dein Zuhause und überwache den Energieverbrauch über OPC UA. Du kannst ein Dashboard erstellen, das den Energieverbrauch in Echtzeit anzeigt, sowie historische Daten sammelt, um Trends zu analysieren und Energieeinsparungen zu identifizieren.

- Mini-Produktionslinie (z.B. 3D-Druck) mit OPC UA überwachen

Falls du mehrere Maschinen hast, wie z.B. 3D-Drucker, Fräsmaschinen oder kleine CNC-Maschinen, kannst du diese miteinander vernetzen und über OPC UA überwachen. Du könntest Zustände wie Betriebszeit, Temperatur, Fehler und Produktionsfortschritt auf einem OPC UA-Server sammeln und visualisieren.

- OPC UA-basierte Wetterstation

Richte eine Wetterstation ein, die über verschiedene Sensoren (z.B. Temperatur, Feuchtigkeit, Luftdruck, Windgeschwindigkeit) Daten sammelt. Diese Sensordaten können über OPC UA an einen Server gesendet werden, der die Daten speichert und visualisiert. Du kannst auch Vorhersagen und Warnmeldungen basierend auf den gesammelten Daten erstellen.

- Heimautomatisierung mit verschiedenen Protokollen verbinden

Wenn du unterschiedliche Automatisierungssysteme zu Hause hast (z.B. KNX, Modbus, Zigbee), kannst du OPC UA als universelles Protokoll verwenden, um alle Systeme zu verknüpfen und über eine zentrale Steuerung zu überwachen und zu steuern. OPC UA ermöglicht es dir, verschiedene Kommunikationsprotokolle miteinander zu verbinden und Daten aus verschiedenen Quellen zu integrieren.

- Fernüberwachung eines Aquariums oder Gartenautomatisierung

Überwache die Wasserqualität deines Aquariums (Temperatur, pH-Wert, Sauerstoffgehalt) oder den Zustand deines Gartens (Bodenfeuchtigkeit, Temperatur, Beleuchtung) mithilfe von Sensoren, die über OPC UA Daten an ein zentrales System senden. Du könntest Alarme einrichten oder automatische Steuerungen (z.B. Pumpen, Ventilatoren) aktivieren, wenn bestimmte Grenzwerte überschritten werden.

- Heizungssteuerung und Optimierung mit OPC UA

Verbinde deine Heizungsanlage mit einem OPC UA-Server und überwache die Temperatur in verschiedenen Räumen deines Hauses. Du kannst die Daten analysieren und Regelalgorithmen erstellen, um die Heizungsleistung zu optimieren, beispielsweise durch Anpassung der Heizungszeiten je nach Außentemperatur und Anwesenheit im Haus.

- Hausüberwachung und Sicherheitssteuerung

Integriere Kameras, Bewegungssensoren und Alarmsysteme in ein über OPC UA gesteuertes Sicherheitsnetzwerk. Du kannst die Sensoren in deinem Haus überwachen und Benachrichtigungen erhalten, wenn Bewegungen erkannt oder bestimmte Schwellenwerte überschritten werden.

- IoT-Dashboard für Hausgeräte

Baue ein IoT-Dashboard, das den Zustand deiner Hausgeräte überwacht und Informationen über deren Nutzung sammelt. Geräte wie Waschmaschinen, Kühlschränke oder Backöfen könnten über OPC UA miteinander vernetzt werden, um Betriebszeiten, Energieverbrauch und Fehlermeldungen zu erfassen.

- Home-Labor: Simulation einer Industrieanlage

Richte eine kleine “Industrieanlage” bei dir zu Hause ein, z.B. eine automatische Sortieranlage, eine Flaschenabfüllanlage oder ein automatisches Lagersystem. Verwende OPC UA, um verschiedene Sensoren, Antriebe und Steuerungen zu vernetzen und die gesamte Anlage über ein zentrales System zu überwachen und zu steuern. Hier kannst du auch Sicherheitsfunktionen und Echtzeit-Überwachung implementieren.

- Anbindung eines OPC UA Servers an die Cloud (z.B. AWS IoT oder Azure IoT Hub)

Du kannst Daten aus deinem OPC UA-Netzwerk in die Cloud senden, um die Informationen global zu überwachen und zu steuern. Verbinde deinen OPC UA-Server mit einer Cloud-Plattform wie AWS IoT oder Azure IoT Hub, um dein Heimnetzwerk mit Cloud-basierten Dashboards oder Steuerungen zu kombinieren.

- Mensch-Maschine-Schnittstelle (HMI) mit OPC UA entwickeln

Entwickle eine grafische Benutzeroberfläche (HMI), um die verschiedenen Steuerungssysteme in deinem Zuhause zu überwachen. Die HMI könnte über OPC UA mit verschiedenen Sensoren und Geräten kommunizieren und dir ermöglichen, alle Systeme zentral zu steuern.

- Virtuelle Maschine oder Simulator für Industrie 4.0-Anwendungen

Erstelle eine virtuelle Simulation einer Industrie 4.0-Produktionslinie bei dir zu Hause. Du kannst eine Software verwenden, um Maschinen und Produktionsabläufe zu simulieren, die dann über OPC UA überwacht und gesteuert werden. So kannst du dich auf den Einsatz von OPC UA in echten Industrieprojekten vorbereiten.

- Optimierung des Lüftungssystems zu Hause

Steuere dein Lüftungssystem intelligent, indem du Daten von CO2-Sensoren und Temperatursensoren über OPC UA sammelst. Du kannst Algorithmen zur Steuerung der Lüftung in Abhängigkeit von Raumluftqualität und Temperatur entwickeln.

Diese Projekte geben dir nicht nur praktische Erfahrungen mit OPC UA, sondern helfen dir auch, eine fortschrittliche Automatisierung und Vernetzung in deinem Zuhause umzusetzen. OPC UA bietet eine flexible und skalierbare Plattform für die Integration verschiedenster Geräte und Systeme, was es ideal für Heimprojekte macht.

Siemens sinamics v90

Beginner Projects:

- Basic Positioning Control: Use your V90 servo to perform simple point-to-point positioning with a start and stop button.

- Speed Control via Potentiometer: Control the speed of the V90 servo using an analog input from a potentiometer.

- Jogging Control: Implement a jog function to manually move the servo forward or backward using two buttons for direction control.

- Timer-Based Motion: Program the servo to move at specific time intervals. For example, move 90 degrees every 5 seconds.

- Position Control Using HMI: Use an HMI to enter a desired position and have the servo move to that position.

- Automatic Door Opener: Control the V90 servo to open and close a door based on sensor inputs (e.g., proximity or motion sensor).

- Turntable Control: Build a turntable that rotates to preset positions, controlled via the V90 servo, useful for exhibitions or testing setups.

- Basic Conveyor System: Use the V90 servo to control the movement of a small conveyor belt, implementing start/stop and speed control.

- Servo with Limit Switches: Set up limit switches to stop the servo when it reaches the desired end points.

Intermediate Projects:

- Pick-and-Place System: Program the V90 servo to control the arm of a pick-and-place robot that can move items from one location to another.

- Simple CNC Machine: Build a basic CNC setup where the V90 servo controls the X or Y axis to engrave simple shapes.

- Servo-Controlled Gate for Parking: Automate a parking gate where the V90 servo opens or closes the barrier based on vehicle detection.

- Rotary Indexing Table: Create a rotary indexing table where the servo moves the table to precise angular positions for assembly or inspection tasks.

- Servo-Driven Bottle Filling System: Use the V90 servo to control the position of a nozzle in a bottling system, moving to the correct position for each bottle.

- Sliding Door Mechanism: Automate a sliding door mechanism with smooth motion, using the servo for precise open/close control.

- Robotic Arm Axis Control: Use the V90 servo to control one or more axes of a small robotic arm, performing basic pick-and-place operations.

Advanced Projects:

- Servo-Controlled 3D Printer Axis: Use the V90 servo for precise control of one axis of a custom 3D printer, improving print quality and accuracy.

- Multi-Axis CNC Milling Machine: Implement the V90 servo in a multi-axis CNC milling machine, controlling one or more axes for accurate cutting operations.

- Robotic Exoskeleton Joint Control: Design a wearable robotic exoskeleton where the V90 servo controls one or more joints for assistance or rehabilitation.

- Advanced Sorting System: Create a sorting system where multiple V90 servos control various conveyors or robotic arms to move items based on size, weight, or color detection.

PLC Projects for SocialMedia

Beginner Projects:

- Simple Start-Stop Motor Control: Control a small DC motor using start/stop buttons and relays, which you can easily simulate with LEDs if motors are not available.

- Timer-Based Lighting System: Set up a lighting system controlled by a timer, perfect for simulating home automation.

- Garage Door Opener Simulation: Use a small motor or servo to simulate opening and closing a garage door with limit switches for end positions.

- Automatic Fan Control: Use a temperature sensor to turn a fan on or off depending on room temperature, a good project for personal comfort.

- Water Level Monitor: Create a simple water tank level control system using float switches or ultrasonic sensors to turn a pump on or off.

- Flashing Lights with Timer: Use a PLC timer to make a set of LEDs flash in sequence, great for understanding timing logic.

- Buzzer Alarm System: Build a basic alarm system where a buzzer sounds when a sensor (like a PIR motion sensor) detects movement.

- Temperature Display with LED Indicators: Use a temperature sensor and LEDs to show if a room is too hot, too cold, or at the perfect temperature.

- Simple Conveyor System: Simulate a conveyor belt using small DC motors and sensors to detect when an object reaches a specific point.

- Automatic Gate Control: Use proximity sensors and a motor to create an automatic gate that opens and closes based on an approaching object.

Intermediate Projects:

- Mini Elevator System: Simulate a small elevator with a motor, limit switches, and buttons for floors. Use LEDs to represent floors.

- Automatic Watering System: Use moisture sensors and a relay-controlled pump to automatically water plants when the soil is dry.

- Temperature Control for a Heater: Use a thermostat or temperature sensor and control a heating element or fan to keep the temperature within a set range.

- Bottle Filling System: Simulate a bottle filling system using small pumps or solenoid valves to control liquid flow into containers.

- Motion-Activated Lighting: Use a PIR sensor to detect movement and activate a light or LED, ideal for simulating automated lighting in rooms or outdoor areas.

- Simple Alarm System: Create a system where a buzzer is triggered when a door is opened (use a magnetic reed switch or limit switch).

- Small Conveyor Sorting System: Build a mini sorting system using sensors to detect object size or color, activating different actuators to direct objects.

- Fan Control with Speed Adjustment: Control a fan using a potentiometer or temperature sensor to vary its speed based on input conditions.

- Home Automation System: Program your PLC to control lights, fans, and other appliances in your home based on timers or manual switches.

- HMI Display for Temperature Control: Use a simple Human-Machine Interface (HMI) or a basic display to show temperature readings from a sensor.

Advanced Projects:

- Automatic Pet Feeder: Build an automated system that dispenses food at specific times or when triggered by a sensor.

- Robotic Arm Control: Use a PLC to control a small robotic arm for pick-and-place tasks, using servos or DC motors for movement.

- Smart Irrigation System: Create a more advanced irrigation system that uses soil moisture, temperature, and humidity sensors to control multiple water valves.

- Mini Packaging System: Design a system where small items are packed into containers using a conveyor and sensors to detect when to stop/start the belt.

- Greenhouse Climate Control: Use sensors to monitor temperature, humidity, and light levels, and control fans, heaters, and lights to optimize plant growth.

- Home Security System: Integrate motion sensors, door/window sensors, and alarms to create a DIY home security system controlled by your PLC.

- Basic CNC Machine Control: Build a small-scale CNC machine using stepper motors controlled by a PLC to engrave or cut simple shapes.

- Energy Monitoring System: Use current sensors to monitor the power consumption of home appliances and display the data on an HMI or log it.

- Mini Factory Automation System: Simulate a small factory setup where sensors detect parts on a conveyor belt and actuators perform actions like sorting or assembling.

- Smart Fan with IoT: Create a fan control system that you can monitor and control remotely via a web interface, using a PLC with IoT capabilities.

Siemens G120 VFD,

Beginner Projects (Foundations & Basics)

- Basic Motor Start/Stop with G120

Use a KTP panel to control the motor (start/stop, forward/reverse).

Learn: Digital I/O, HMI buttons, drive commissioning in TIA Portal.

- Speed Control via HMI (KTP)

Add speed input via HMI slider or numeric entry.

Learn: Drive parameters (r2090), analog/digital control methods.

- Display Drive Status & Faults on HMI

Show run status, speed feedback, and faults on KTP or Unified panel.

Learn: Diagnostic buffer, PLC-to-HMI tags, drive feedback mapping.

Intermediate Projects (Drive + Safety + Unified Panel)

- Safe Torque Off (STO) with S7-1500F

Wire STO via F-DI, create a safety program to control drive enable.

Learn: Safety blocks, F-START, fail-safe wiring.

- Automatic Conveyor with Speed Profiles

Motor ramps through different speeds at timed intervals.

Learn: Ramp-up/ramp-down control, drive command sequencing.

- Drive Jog Mode with HMI Selection

Implement jog buttons (forward/backward) from the Unified Panel.

Learn: HMI interlocks, momentary/hold logic.

- Local/Remote Mode Switching

Enable control from HMI (remote) or drive panel (local).

Learn: Control word management, mode status.

Advanced Projects (Process Simulation & System Integration)

- PID Speed Control via HMI

Use a Unified Panel to set a PID setpoint (e.g., for tension control).

Learn: PID_TUNE block, feedback loops, analog inputs.

- Simulated Pump Station with Flow Control

Adjust flow rate with the VFD and simulate tank levels.

Learn: Analog sensors (simulated), speed-feedback loop.

- Alarm & Fault Logging System on Unified Panel

Display faults from the drive and PLC with timestamps.

Learn: HMI alarm configuration, event management.

- Recipe Management for Drive Parameters

Change acceleration, deceleration, and max frequency using recipes.

Learn: Unified Panel recipe editor, drive parameter updates from HMI.

- Dynamic Safety Zones for Variable Speed

Change safe speed limits based on operating mode (e.g., maintenance mode).

Learn: PROFIsafe parameterization, F-blocks logic, Safety Matrix.

Pro-Level Projects (Industrial System Simulation)

- Energy-Efficient Conveyor System

Monitor power consumption (r0038), optimize motor speed dynamically.

Learn: Energy data collection, performance profiling.

- Multi-Motor Coordination

Simulate 2+ motors where one VFD (master) controls the others (follower/slave).

Learn: Drive synchronization, communication via PLC.

- Integrated Maintenance Panel

HMI shows drive run hours, load profiles, and gives maintenance reminders.

Learn: Data logging, integrated diagnostics.

Nice